Advanced technology

The FLEXLIFT robot system is integrated into the machine control system via the OPC UA communication standard. This communication platform creates ideal conditions for this with its manufacturer and language-independent technology. One dataset for machine and robot helps to save time and to increase reliability of your processes.

High flexibility

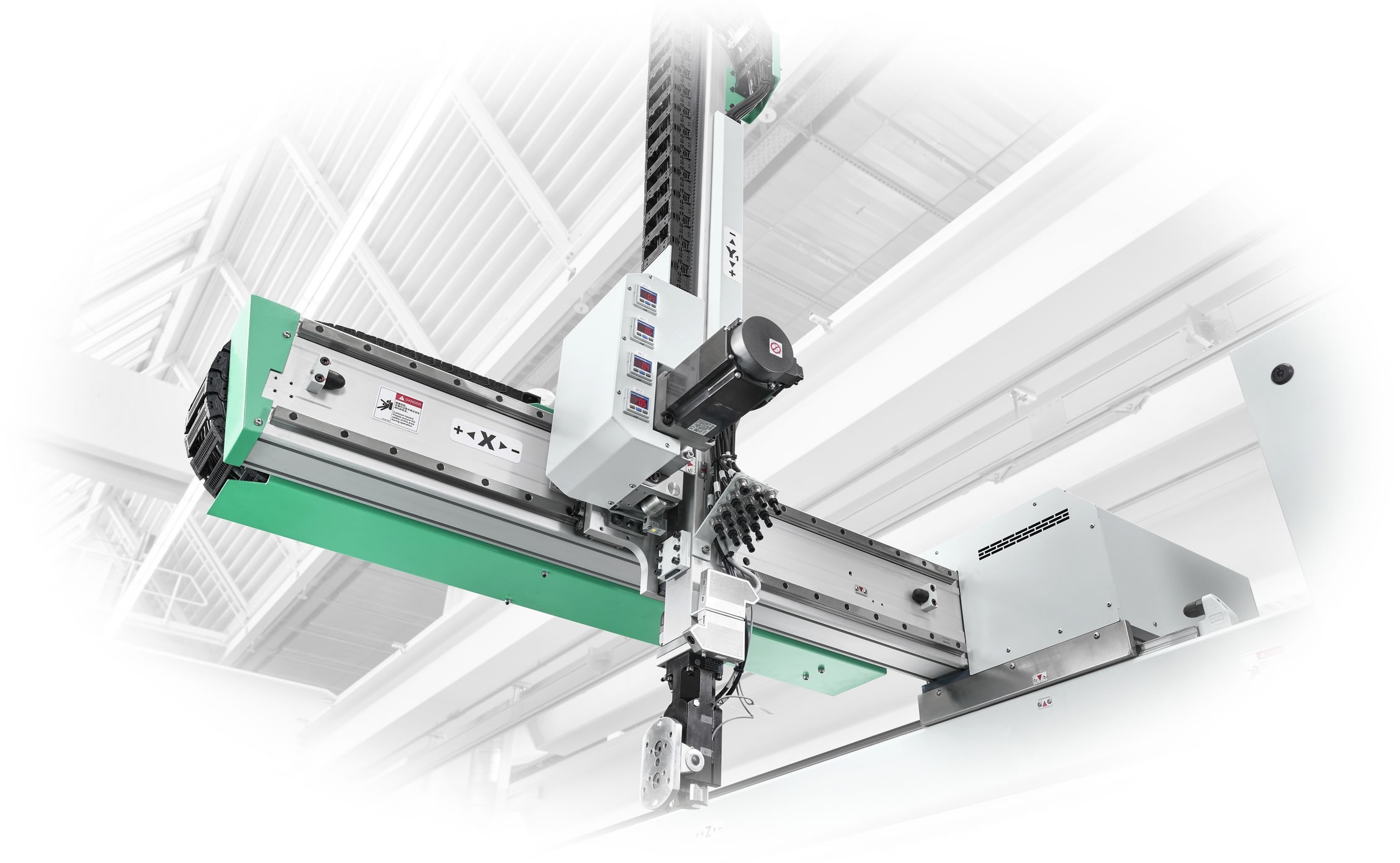

FLEXLIFT provides wide range of pay load and optional selections to meet customers’ requirements. The dynamic vertical axis enables even shorter mould entry times. Its telescopic design makes it suitable for small spaces. Also available: pneumatic and vacuum connections for end-of-arm tooling (EOAT) and peripheral interfaces. This means high flexibility and significant cost reduction.

High efficiency

Top quality and performance: we implement these principles consistently with our FLEXLIFTs. The robust, low-maintenance technology ensures a long service life and high availability. Our reliable servo motors reduce vibrations during high speed movements, thus ensuring accurate pick-up of the parts. Axis speeds can also be decreased when suitable in order to save energy and reduce wear.

Benefits FLEXLIFT

Control system – engineered by ARBURG

Control system – engineered by ARBURG

HMI follows standard from ARBURG's control system. User-interface is friendly to set-up and use: programming style fitted for Asian market. Two-level administrative authority makes the on-site management easier. Number of I/O can be expanded up to 256 which leaves space for further retrofitting.

Optional “encapsulated” design

Optional “encapsulated” design

Dust and powder proof design - Stainless cable support to reduce wear of components and collect powder. Dust and grease collector at end of the Y axis. A groove on Z axis (mold side) to collect oil and grease. Filter the exhausted air from vacuum generator. Friendly to clean room and medical industry.

High reliable servo motor

High reliable servo motor

Perfect vibration control under high speed movement and stop. Automatically warn when motor and belt are overload. Speed out of mold is adjustable - reducing power consumption and wear of component. Save energy and cost of spare parts.

EUROMAP 67 and OPC UA are as standard

EUROMAP 67 and OPC UA are as standard

For you, this means increased ease of use, for example through a shared data set for your machine and robotic system to achieve central machine controlling, program of robot and machine synchronized and prevention of crashes between mould and EOAT.

Linear robotic system FLEXLIFT

Automated production cells

Combine your injection moulding machines, robots and extensive peripheral equipment into your own individual turnkey system using us as your system supplier. Our experts can advise you from the initial idea to the finished project and tailor the technology precisely to your needs.

This might also be of interest

From practical experience – for practical use. That's how we share knowledge. You benefit from our know-how. Targeted, fast, and cooperative. With our machines, for your purposes.

Electronics, medicine, mobility, packaging, complex components for a wide range of sectors and industries. This is where you excel. So do our machines and solutions.

The multitude of industries, technologies and applications is sure to include an example that meets your requirements. Draw inspiration for new ideas from our selection of components.